Thermocapillary Convection Potential by

Evaporative Cooling Effects during Spin Coating

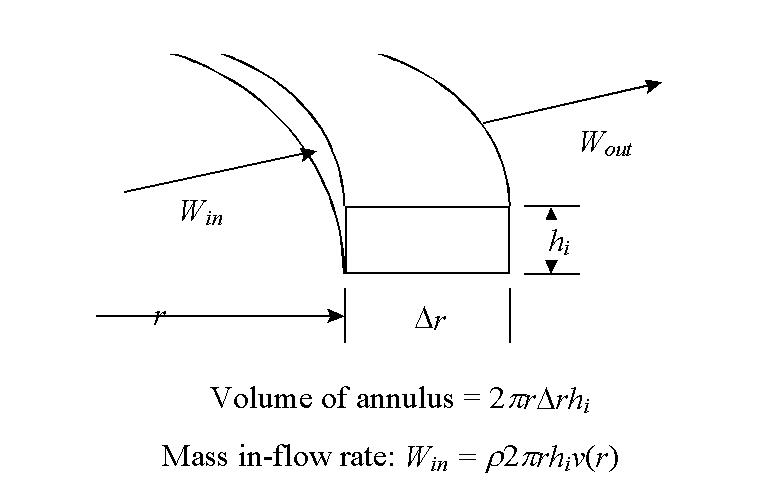

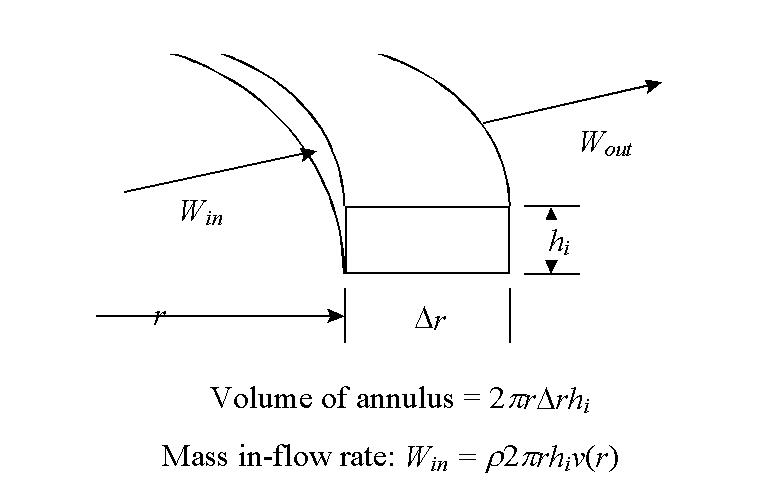

We developed

a finite element model including heat transfer, fluid flow, and solvent

evaporation effects. The solvent evaporation causes evaporative cooling

at the top surface of the spinning solution on the wafer (also subjected

to continually thinning via simple viscous flow). Individual coating elements

were modeled and fluid in-flow and out-flow were both carefully considered:

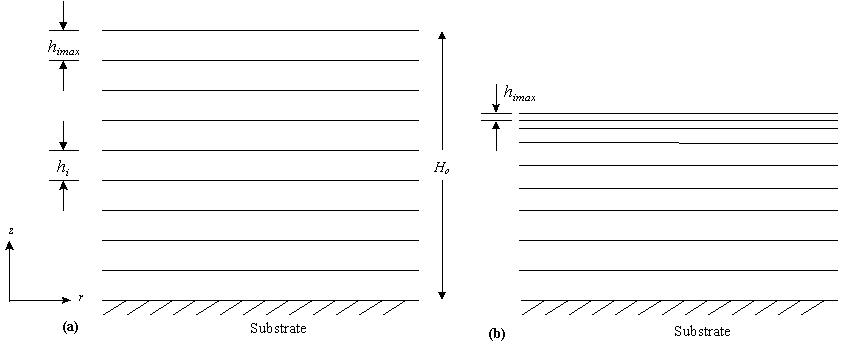

As a result

of the force balances, the upper layers thin faster than the lower ones.

So the relative evolution of the thickness grid evolves like this schematic

shows:

Using this model (including the temperature of each layer as well as its thickness) then we were able to show that thermocapillary instability may be driven only very early on in the process. At these early times the temperature gradient is still quite steep and the fluid layer is still thick enough. At later times the fluid has thinned so much that the Marangoni number drops below the critical value.

This has implications for composition-driven capillary effects: mass diffusion is much slower than thermal diffusion -- demonstrating that soluto-capillary effects will be much stronger in the long run and have much greater potential to instigate roughening instabilities. This is currently under study.

This work has been submitted for publication and is currently under review.

Page completed 24 July 2000

(c) 2000, 2005 Dunbar

P. Birnie, III